Equipment

Reverse Osmosis

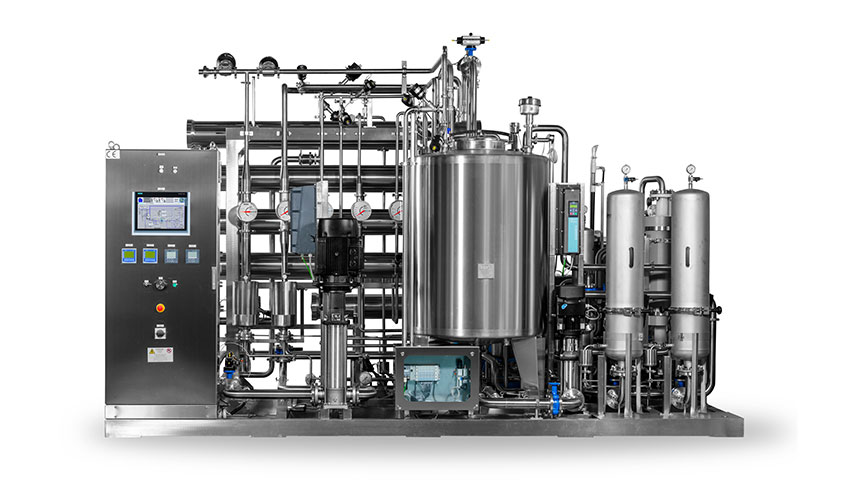

Pharma RO is our response to the demand for Purified Water that meets the stringent requirements of international pharmacopoeias, even from feedwater with a high viable load.

This advanced system is the culmination of years of experience and continuous technical development.

Pharma RO is an innovative platform based on a double pass Reverse Osmosis system, providing unparalleled flexibility and robustness with a strong emphasis on sustainability.

The plant is meticulously designed and constructed to meet the highest quality standards.

Pharma RO can generate from 300 to 30.000 l/h of PW, while the self-modulating valves allow users to dial in required flowrates.

Technical description

Operating Principle

The purification process begins with softened feed water pre-filled into a break tank. Subsequently, following final filtration, a circulation pump and high-pressure pump feed the first stage of membranes. The number of membranes in this stage determines the processing capacity. The osmosed water produced then undergoes a further pump system, entering the second pass of membranes, while the concentrate is rejected. The purified water is directed to storage, and the second stage concentrate is efficiently recovered to the break tank for consumption optimisation.

The tank, pumps, and filter of the first stage are also instrumental in chemical washing and sanitising the membranes, ensuring thorough maintenance. With an exclusive design by Stilmas, the plant configuration ensures peak performance and operation flexibility. It allows for periodic recirculation during stand-by conditions, effectively controlling bacterial contamination.

Sanitisation process

The system offers two sanitisation methods: chemical sanitisation (standard version) or heating-based sanitisation (available on request). For chemical sanitisation, a low-concentrate H2O2 solution is circulated. This is a non-dangerous chemical and is easily removed from the process at the end (H2O2 naturally converts into H2O). Alternatively, on request, the plants can be equipped with a steam-heated exchanger and membranes and EDI modules suitable for hot water circulation.