Solutions

We're the experts in providing clean utilities solutions

Clean Utilities generation units installed

global and local clients worldwide

production facilities and commercial hubs

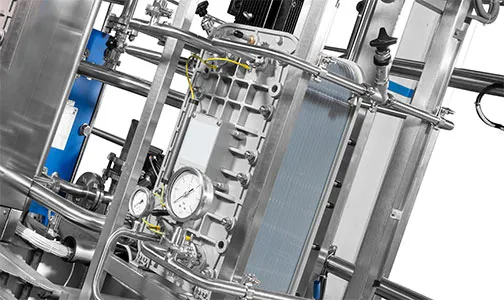

WFI generation

Water for Injection (WFI) can be defined as high-purity water without significant contamination. It is the main excipient used in the production of parenteral drugs and other Life Science applications.

It can be produced using several technologies including Distillation using Multiple Effect (ME), Vapor Compression (VC), and Membrane filtration.

PW generation

Purified Water (PW) is obtained through various purification steps involving physical and chemical processes including filtration, ion-exchange (IEX), reverse osmosis (RO) and others. It is then used as an excipient in the production of non-parenteral preparations and other pharmaceutical applications.

UPW generation

UltraPure Water (UPW) is highly purified water, free of all sub-micron contaminants, produced through advanced filtration processes like reverse osmosis, deionization, and ultraviolet oxidation. In microelectronics, EV battery, and semiconductor manufacturing, UPW is crucial for maintaining product integrity and preventing contamination, ensuring high quality and performance in sensitive processes.

PS generation

Pure Steam (PS) is steam that, when condensed, meets the same requirements as Water For Injection (WFI). It is a clean utility primarily used in the pharmaceutical industry for sterilising product-contact components and humidifying cleanrooms and isolator air supplies.

Storage, Distribution, Turnkey Systems

We design Storage and Distribution systems to provide water to POU at the required location, flow, temperature and pressure while minimizing microbial growth and maximizing efficiency. Stilmas is the perfect partner to provide the all-in-one solution, from design to installation of complete clean utilities turnkey systems.

Pretreatment

Pretreatment is the first step in many purification processes; it is composed by a variable number of operation units, and prepares the water for the final purification step. It removes biologicals, particles, colloidals, organics, minerals and oxidant fouling from water and it is essential for the performance and durability of the purification equipment.

Revamping

In most cases, the obsolescence of an equipment is related to instrumental and electronic parts and components, like control systems. Stilmas Service department is able to provide the full overhauling of existing systems, including a relevant change control.

Lab Water Generation

High Purity Water is essential to various industries and scientific applications. This specialized form of water is meticulously purified to remove impurities, minerals, and contaminants.

The production of High Purity Water involves a multi-step purification process, typically including deionization, reverse osmosis, and other advanced filtration techniques that effectively eliminate ions, particles, and organic compounds, achieving a level of purity far surpassing that of regular tap water or even distilled water.